POLYELITE®

Primary Containers

High-quality and Functional ready-to use bags for IV drugs

POLYELITE®

POLYELITE® is the brand of primary packaging for pharmaceutical applications with excellent propeties and safeness.

Compliance of ISO 9001 and 15378

Medix Showa Co., Ltd. has received ISO 15378:2017 certification, which scope is “Design and development, manufacture and distribution of Infusion bag” and ISO 9001:2015 certification which scope is “Design and development, production and distribution of plastic containers”.

POLYELITE® is registered in DMF.

production facility : Medix Showa Co., Ltd. (Nagano, Japan)

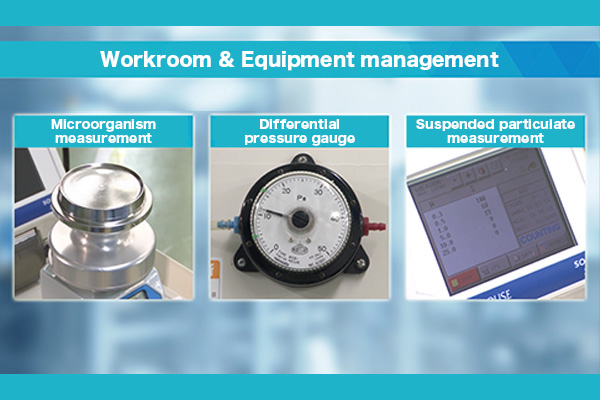

POLYELITE® is manufactured in the ISO class 7 clean room.

Products

Polyethylene Bag for Steam Sterilization

POLYELITE® TH82

- Made of polyethylene resins only

- Applicable to a wide range of temperatures from -80℃ to +123℃

- Excellent mechanical properties at very low temperature

- Extremely low extractables and leachables

- JP 7.02-2.1 Polyethylene or Polypropylene Containers for Aqueous Injection

- USP<661.2> Plastic Packaging System for Pharmaceutical Use

- USP<87> Biological Reactivity Tests, in vitro

- USP<88> Biological Reactivity Test, in vivo, Plastic Class VI

- USP<85> Bacterial Endotoxins Test

- USP<788> Particulate matter in injections

- EP 3.2.2.1. Plastic Containers for Aqueous Solutions for Infusion

Sorption-free Bag for Steam Sterilization

POLYELITE® PHC

- Cyclo-olefin polymer layer as a contact layer

- Extremely low sorption of lipid-soluble drug substances

- Excellent transparency after steam sterilization

- Extremely low extractables and leachables

- JP 7.02-2.1 Polyethylene or Polypropylene Containers for Aqueous Injection

- USP<661.2> Plastic Packaging System for Pharmaceutical Use

- USP<87> Biological Reactivity Tests, in vitro

- USP<88> Biological Reactivity Test, in vivo, Plastic Class VI

- USP<85> Bacterial Endotoxins Test

- USP<788> Particulate matter in injections

- EP 3.2.2.1. Plastic Containers for Aqueous Solutions for Infusion

Polyethylene Bag for Bio-pharmaceuticals

POLYELITE® EL

- Additive-free polyethylene film and bag

- Excellent mechanical properties at very low temperature

- Applicable to storage at liquid nitrogen temperature

- Extremely low extractables and leachables

- JP Polyethylene or polypropylene containers for aqueous injections

- USP <661> Physicochemical tests

- USP <87> Biological reactivity tests, in vitro

- USP <88> Biological reactivity tests, in vivo; Plastic Class VI